Experts from the National Research Nuclear University MEPhI have obtained a number of ultra-thin multi-layered films that can form the mainstay of the future electronics and power sectors. These results were made possible by conducting research for singling out fundamental conditions for the thermal-chemical synthesis of hetero-structures based on transition metals’ di-chalcogenide compounds MoS2, WS2, MoSe2 and WSe2.

Ultra-thin films of transition metals’ di-sulfides and di-selenides, including molybdenum and tungsten, absorb light quite effectively because very small crystal lattices of transition metals’ di-chalcogenide compounds can absorb light without the need of phonons (crystal-lattice fluctuations).

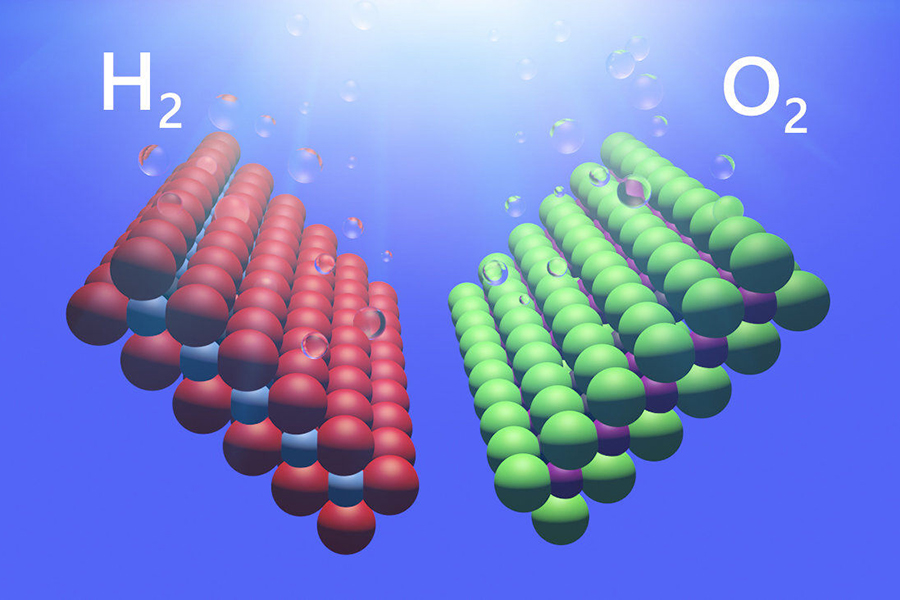

Photogeneration of solar fuels components by splitting water with the use of nanocatalysts based on di-chalcogenides of transition metals

At the same time, the surface of such nano-crystals can create favorable conditions for splitting water molecules into hydrogen and oxygen. This turns ultra-thin films of transition metals’ di-chalcogenide compounds into highly promising material for the photo/electric catalysis process and for developing numerous modern optical-electronic devices, including photo detectors and photo-voltaic converters.

“It is very important to form a multi-layer film by creating optimal conditions for making separate layers of transition metals’ di-chalcogenide compounds that will not cause any disruptions inside the preliminarily applied thin-film layer featuring another di-chalcogenide compound of transition metals. We have studied the conditions for obtaining high-quality ultra-thin films of transition metals’ di-chalcogenide compounds using a method for the thermal-chemical processing of metal and metal-oxide precursors (molybdenum and tungsten) by sulfur or selenium fumes and also inside a hydrogen-sulfide atmosphere,” told an Engineer Dmitry Fominsky, an expert on the pulse-laser spray-coating of ultra-thin films and nano-structures.

According to Fominsky, the new films were studied using a combination of modern methods, including gamma-ray and scanning electron microscopes, the combined light-dispersion spectroscopy and X-ray photo-electron spectroscopy. They showed that the transformation of molybdenum-containing film inside sulfur or hydrogen-sulfide fumes depended on the chemical composition of the initial precursor, created using the pulse-laser spray-coating method.

The use of the pulse-laser spray-coating method made it possible to prepare a thin film/primer with a preset thickness and chemical composition. This helped scientists determine specific conditions for the effective sulfidizing of Mo and Mo/Ox films and to obtain ultra-thin MoS2 films at temperatures below 500 degrees Celsius.

“We have also obtained films of transitional metals’ di-selenide compounds, including tungsten di-selenide, with an almost perfect H2 crystal lattice. Therefore it becomes possible to obtain ultra-thin semi-conducting films of the Mo (W) SxSe2-x type; and their useful properties are regulated by the concentration of metals (W/Mo) and chalcogens (S/Se),” Fominsky noted.

Researchers presented the results of their experiment at the 16th international school-conference New Materials: Tolerant Nuclear Fuel. They point out that technological and temperature parameters for creating molybdenum and tungsten selenide sulfides largely overlap. However, as MEPhI specialists explained, it is possible to create favorable conditions for obtaining ultra-thin films with preset structural and chemical properties using various metal and metal-oxide precursors and chalcogen-containing active media.

As the films are capable of acting as photo-catalysts, this will make it possible to more effectively obtain solar-fuel components, including hydrogen and oxygen, from water and without using expensive platinum-group materials.