A titanium-based alloy was developed for brazing the anodes of X-ray machines for computed tomography and angiography at the Department of Physical Problems of Materials Science (№ 9) of the Institute of Nuclear Physics and Engineering (INPhE). The results have been published in the Welding Journal.

Similar anodes are produced in Germany, the USA, and Japan. Compared with existing foreign analogues, the new alloy-solder has a number of advantages: low melting point, the possibility of obtaining a heat-resistant molybdenum-graphite compound with operating temperature up to 1700° С, high fluidity, etc.

“Research work resulted in development of a method for soldering molybdenum and graphite using the created alloy-solder. The patent application was filed for the received technique,” noted the chief developer of solder, the post-graduate student of the Department № 9 Ivan Fedotov.

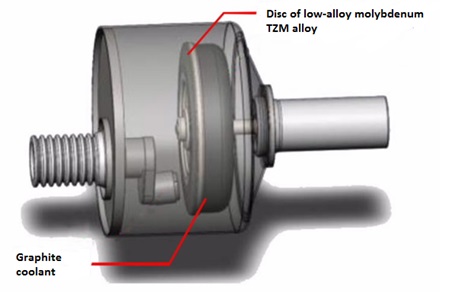

The anode of the X-ray tube consists of two elements: a disc of low-alloy molybdenum TZM alloy with a deposited tungsten coating and a graphite cooler, and is designed to produce X-rays by deceleration of an electron beam with a power of about 100 kW. In the operating mode, the anode rotates at a speed of 9000 rpm for uniform distribution of heat load.

A new alloy-solder will reduce the cost of manufacturing anodes, and also increase their reliability by obtaining a heat-resistant joint.