Specialists from the National Research Nuclear University MEPhI together with colleagues from the Moscow State University of Geodesy and Cartography, the Institute of Structural Macrokinetics and Materials Science RAS, and the Baykov Institute of metallurgy and material science RAS have developed a technology to produce compacts from aluminum oxynitride (ALON). An article on the subject was published in "IOP Conference Series: Materials Science and Engineering".

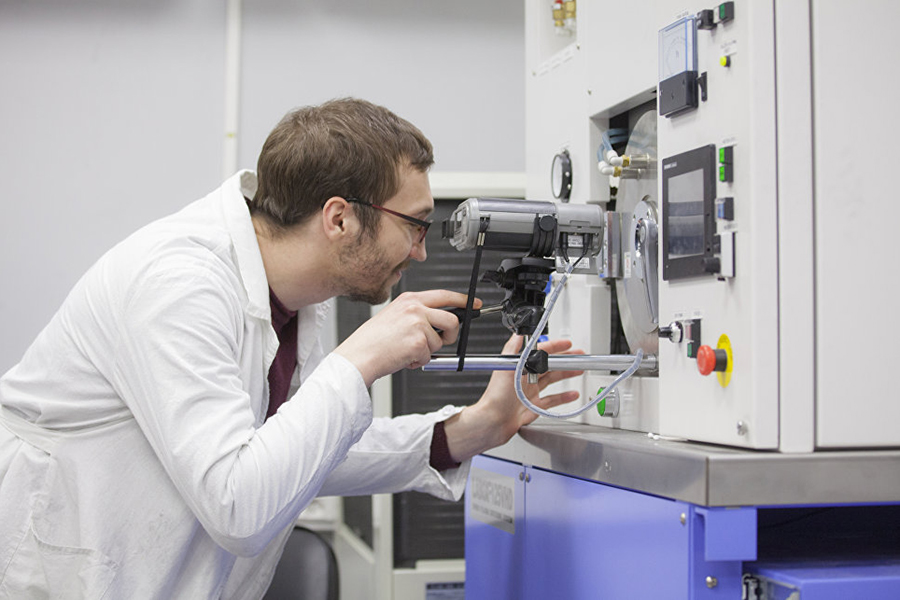

To obtain the “transparent aluminum” researchers at the Institute of nuclear physics and engineering (INPhE) MEPhI applied the method of spark-plasma sintering.

Spark-plasma sintering is a new sintering process, which is based on the modified method of hot pressing. In this case electric current is passed directly through the mold and rpessing billet, but not through an external heater. Very rapid heating is achieved by pulsed current for an extremely short work-cycle time.

Postgraduate student of INPhE Nikita Rubinkovskii

“Among all present ceramics of medium density aluminum oxynitride has a significantly high strength, comparable to that of YAG ((yttrium aluminum garnet) and cubic zirconia (stabilized zirconium oxide). Its’ toughness, which is the most important characteristic for armor protection, surpasses those of all transparent materials including quartz glass: fused quartz, spinel and leucosapphire,” explains one of the authors of the publication, postgraduate student of INPhE Nikita Rubinkovskii.

Fans of the “Star Track” remember that in the fourth movie “The Voyage Home” quite an important role in the story is played by a material called “transparent aluminum”. It was a material of the windows at the USS Enterprise spacecraft. In fact, such materials have already been created and successfully used in the art, for example, ALON. It's four times higher than aluminosilicate glass in strength and scratch-resistance. In addition, this material is able to withstand temperatures up to 2100 degree Celsius.

Currently, there is a growth in penetrating power of small arms and small-caliber artillery that forces the developers of protection equipment to seek adequate opportunities to improve the performance of armor materials and protective structures. This is especially true of transparent armor materials. Transparent polycrystalline ceramics is the most promising in this respect, in particular, ceramics based on aluminum oxynitride. It is possible to obtain transparent products of complex shape using the traditional for ceramics technologies processes of molding and sintering.

The developers also claim that ALON can be used in several military and commercial applications, e.g., windows and domes for space crafts and outer transparent armor.